Worker trapped in overturned dump truck

In May 2023, a worker sustained crush injuries when they were trapped in the cabin of an overturned dump truck. Early investigations suggested a worker was operating a nine tonne dual view dump truck that rolled over an embankment.

Investigations are continuing.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

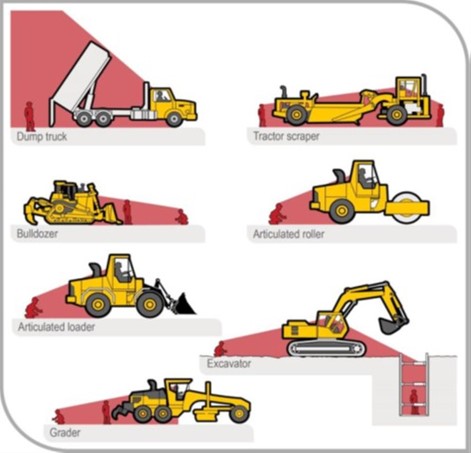

Powered mobile can include trucks, mobile cranes and earthmoving machinery (e.g., rollers, graders, scrapers, bobcats, and excavators). There have been numerous incidents in Queensland where workers have been seriously injured or killed by powered mobile plant.

Mobile vehicles can pose potential risks when:

- it collides or makes contact with people or objects such as other vehicles or plant and energised powerlines

- the vehicle is moving in an uncontrolled or unexpected manner

- the vehicle is overturning

- objects fall onto the operator

- an operator is ejected from the vehicle.

Operators of mobile vehicles can often have severely restricted visibility of ground workers or nearby pedestrians, particularly those close to the vehicle.

Figure 1: Source: WHSQ - Excavation work code of practice 2021

Ways to manage health and safety

Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator you've used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

Employers and self-employed people are required to control the risk associated with vehicles and mobile plant, including the risk of pedestrians being struck by vehicles such as trucks. Before operating any vehicle, the person with management or control must ensure:

- the vehicle selected is right for the task and is fitted with suitable safety features (e.g., enclosed cabin, seatbelts, rear-view mirrors and working audible warning devices, such as horn and reversing beepers)

- the manufacturer's operating instructions have been read and are followed, including:

- the ground slope stability limits for uphill, downhill, and lateral travel

- the recommended travel speed when travelling on slopes or cornering, particularly with a load e.g., low range/low gear

- the relative position of the load in relation to uphill/downhill direction of travel

- the maximum capacity (load) the vehicle can carry.

- they have conducted a risk assessment of the workplace/site location in relation to plant operation and movements and interactions with workers and others

- ground conditions and the intended travel pathways have been inspected and assessed to identify any problem areas (e.g., ground slope, soft or loose ground, tight corners, or blind spots)

- the design and implementation of a traffic management plan, including identifying suitable exclusion zones and vehicle speed limits. They must communicate these to workers and other people in the vicinity before tasks are carried out

- the use of a spotter where required, including suitable means of communication between the spotter and operator (e.g., two-way radio) to assist with safe movement of the vehicle, particularly where there may be blind spots or other workers in the vicinity

- any workers around the vehicle are aware of operator blind spots and exclusion zones

- there is adequate lighting to safely operate the vehicle (i.e., if outdoors, the effect of adverse weather conditions including reduced visibility) has been considered

- trucks are fitted with handbrake alarms to alert drivers if the braking system is not engaged before hopping out

- trucks and mobile plant are properly immobilised before being stored, cleaned or worked on (i.e., positioned on level ground and use of handbrake and wheel chocks)

- information, training, instruction, or supervision is provided as necessary to control the risks associated with the vehicle

- training programs are practical and ‘hands on’ and take into account the particular needs of workers’ literacy levels, work experience, and specific skills required for the safe use of the vehicle

- they implement familiarisation training and supervision for the specific make and model of vehicle until deemed competent

- training on the specific make and model of the vehicle is documented

- worker training, experience and competency aligns with the requirements and complexity of the task

- untrained or inexperienced workers do not operate the vehicle, particularly in unfamiliar or high-risk terrain or for unfamiliar tasks.

PCBUs (person conducting a business or undertaking) must first consider controls that most effectively eliminate the risk or, where not reasonably practicable, minimise the risks. Hazards such as pedestrians being struck by vehicles may also be minimised by implementing administrative controls, so far as reasonably practicable. Administrative controls can include the design and implementation of a traffic management plan.

Any remaining risk must be minimised with suitable personal protective equipment (PPE). For example:

- hard hats, steel cap boots, and high visibility vests

- safety footwear should be:

- suitable for the type of work and environment

- comfortable with an adequate non-slip sole and appropriate tread

- checked regularly to ensure treads are not worn away or clogged with contaminants.

Administrative control measures and PPE rely on human behaviour and supervision. If used on their own, they are not as effective in minimising risks. The control measures you put in place should be reviewed regularly to make sure they work as planned.

More information

- How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB)

- Managing the risks of plant in the workplace Code of Practice 2021 (PDF, 1.57 MB)

- Managing the work environment and facilities Code of Practice 2021 (PDF, 0.57 MB)

- Mobile plant

- Work health and safety consultation, co-operation and co-ordination Code of Practice 2021 (PDF, 0.54 MB)

- Safely immobilising heavy vehicles and trailers campaign

- Traffic management for construction or maintenance work code of practice 2008 (PDF, 0.8 MB)

- Onsite traffic management self-assessment tool (PDF, 0.36 MB)

Have you been affected by a workplace fatality, illness or serious injury?

For advice and support: