Young worker seriously injured by drop saw

In April 2023, a young worker suffered serious hand injuries after an incident on a construction site. Early enquiries indicated the worker was operating a drop saw to cut noggins when for reasons yet to be established his hand came into contact with the moving blade, causing significant amputation injuries.

Investigations are continuing.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

Serious incidents can occur when cutting with power tools such as drop saws. Portable power tools present a range of hazards, including:

- moving parts

- objects being ejected

- vibration

- dust and fumes

- noise

- fatigue

- repetition.

Ways to manage health and safety

Taking steps to manage risks is a condition of doing business in Queensland. Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator that you've used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

A person conducting a business or undertaking (PCBU) has duties under WHS legislation to ensure, so far as is reasonably practicable, the provision and maintenance of safe plant (including drop saws). The legislation includes more specific requirements for PCBUs to manage the risks of plant, as well as other hazards associated with the workplace.

The person with management or control of plant at a workplace must take all reasonable steps to ensure all safety features, warning devices, guarding, operational controls, and emergency stops are used in accordance with the instructions and information provided.

Effective control measures for plant are often made up of a combination of controls. Before using a drop saw or similar, assess the risks and consider whether it is the right tool for the task or whether there is another tool more suitable. Also, consider the option of purchasing timber or other materials that are pre-cut.

Some common engineering risk control measures can include:

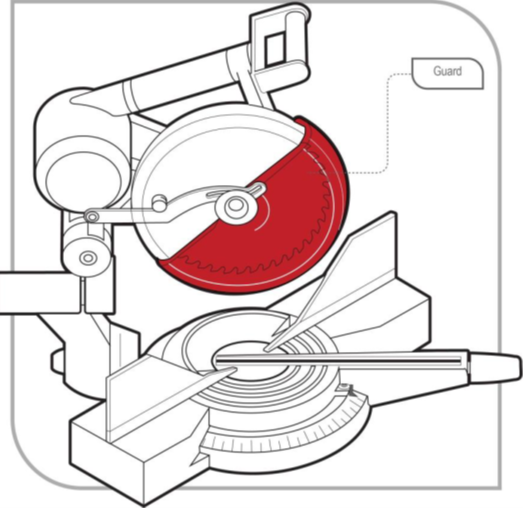

- Guarding of the saw blade and other mechanical parts should be done to prevent inadvertent contact. This can include adjustable guarding that incorporates movable sections or panels of the guard to allow materials to be fed into the guarded area while still preventing physical contact (see Figure 1).

Figure 1: Self-adjusting guard for a drop saw

- Ensuring the drop saw (or similar plant that could move) is adequately secured to prevent unexpected movement. This could include using purpose-designed and engineered support stands, jigs, cradles, or clamps.

- Ensuring work pieces are supported and secured in accordance with the manufacturer’s instructions.

A safe system of work for using drop saws or similar power tools should be implemented and maintained. This could include:

- ensuring the drop saw is inspected, maintained, and repaired according to the manufacturer’s recommendations and specifications (the manufacturer's instructions must be included in a safe work procedure on how inspection and maintenance should be carried out). Visually inspect the saw for damage before use

- inspection and maintenance of the blade prior to use - this is important as poor blade condition can result in extra effort/ exertion in pushing and controlling the cutting direction

- providing information, training, instruction, and supervision to workers who will use the drop saw that includes the development of safe work procedures in accordance with the manufacturer’s instructions. Training and instructions should include the safety warnings (sometimes referred to as the Do’s and Don’ts) that are in the manufacturer’s instructions

- ensuring practical and hands-on training is given to workers, taking into account literacy levels, work experience and the specific skills required for safe use of the equipment. This includes safe work procedures with instructions on:

- the correct use of guarding and other control measures (such as work piece clamps and supports)

- how to safely operate and maintain the plant or equipment

- information on setting up the equipment and the work area to minimise any risks from working in awkward positions

- cleaning processes according to the manufacturer’s instructions.

- consulting with workers to obtain feedback on the drop saw or similar power tools, and associated work processes and safe work procedures

- ensuring the equipment has a current test tag

- safely storing power tools not in use.

Any remaining risk must be further minimised with suitable personal protective equipment. For example, hard hats, protective footwear, eye protection and hearing protection.

Administrative control measures and PPE rely on human behaviour and supervision. If used on their own, they are least effective in minimising risks. The control measures you put in place should be reviewed regularly to make sure they work as planned.

Young workers

Business owners must also ensure the work environment, and the way young employees do their job, is safe and healthy, regardless of the type and terms of their employment.

Employers of young workers should:

- understand their risk profile

- ensure a safe and healthy workplace

- provide information, training, instruction, and supervision

- develop a positive workplace culture.

Consider the tasks you give to new and young workers given their skills, abilities, and experience. Before a young person begins work, a PCBU should:

- identify the gaps in the worker's knowledge and assess their ability to work safely (competency should be tested)

- not accept a young worker's assurance that he or she is experienced and competent.

It's important for young workers to actively participate in the way work health and safety is managed. This means taking induction and training seriously, using the risk management process for work tasks, and asking for help before starting a task they're not familiar with or comfortable carrying out.

More information

- How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB)

- Managing the risks of plant in the workplace code of practice 2021 (PDF, 0.65 MB)

- Young workers (PDF, 0.65 MB)

- Young worker safety toolkit (PDF, 0.65 MB)

- The right start - building safe work for young workers (film) (PDF, 0.65 MB)

- Safety rules for using power tools (film), Safe Work Australia

Have you been affected by a workplace fatality, illness or serious injury?

For advice and support: