Bridge and gantry crane serious incidents

In September 2023, two young workers were injured when a bundle of steel lengths weighing over one tonne fell from a bridge crane (overhead travelling crane). Initial investigations indicate a lifting chain slipped off one end of the bundle of steel while it was being moved using a dual hoist bridge crane inside a warehouse. The bundle fell, striking a worker and a second worker was injured while assisting the first.

In October 2023, a worker suffered serious leg and foot injuries after being struck by a gantry crane wheel. Initial enquiries indicate he was using a jackhammer close to the crane’s rail system when the crane began operating and one of its wheels struck him.

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

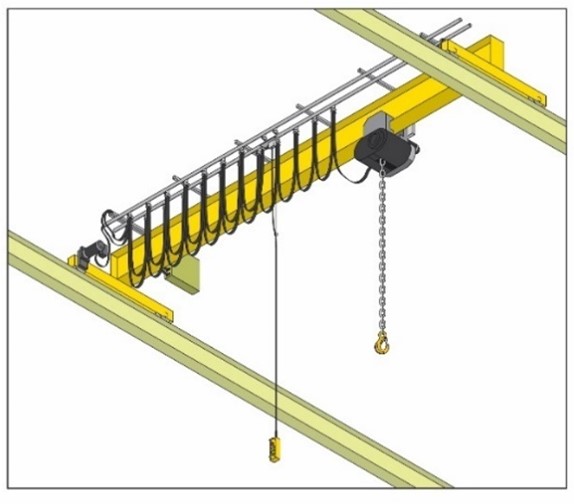

A bridge crane comprises a beam mounted at each end to an end carriage, which travels along elevated runways, with one or more hoisting mechanisms that traverse across the bridge. See Figure 1.

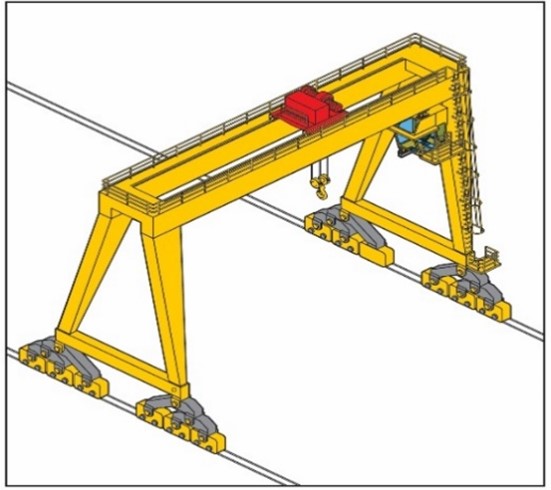

A gantry crane comprises a beam supported at each end by legs mounted on end carriages. It travels on supporting surfaces or deck levels, whether fixed or not, including a crab with one or more hoisting units that traverse across the bridge. See Figure 2.

Figure 1: Bridge crane

Figure 2: Gantry crane

Source: Bridge and Gantry Cranes Information Sheet - Safe Work Australia

Cranes are used to handle heavy loads and so have the potential to cause serious injury or death. Hazards associated with a bridge and gantry crane include but are not limited to:

- failure of worn or damaged mechanical components

- background noise hindering communication

- poor lighting

- multiple cranes on the same runway.

Ways to manage health and safety

Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator that you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

The Work Health and Safety Act 2011 includes duties for persons conducting a business or undertaking, owners and suppliers of plant. In addition, the Work Health and Safety Regulation 2011 includes specific duties for a person conducting a business or undertaking with management or control of plant, including plant that lifts or suspends loads.

A crane owner’s responsibilities include, but are not limited to ensuring:

- safe systems of work are used when the crane is operated

- there’s a thorough maintenance and inspection program

- equipment is maintained and inspected in accordance with the crane manufacturer’s requirements and other relevant technical standards

- that only people with the appropriate crane training or high risk work licence (if applicable) operate the crane.

Planning and coordinating crane operations

Planning for bridge and gantry crane operations should start as early as possible. This includes but is not limited to:

- consultation with everyone engaged in the work within the working area of the crane

- implementing effective exclusion zones around the crane and adjoining areas to prevent people from entering the area (the size of the exclusion zone should be based on a written risk assessment) and ensuring those involved in the lift do not get under a suspended or partially lifted load.

High risk work licensing

A CB class high risk work licence includes bridge and gantry cranes that are controlled from a permanent cabin or control station on the crane, or remotely controlled with more than three powered operations. Powered operations include:

- north/south

- east/west

- up/down

- rotating attachment

The CB high risk work licence includes the application of load estimation and slinging techniques to move a load.

In most situations a dogging (DG) high risk work licence will be required for persons who select lifting slings and sling the load. A worker with a CB high risk work licence can carry out limited slinging of loads without holding a DG high risk work licence.

Crane operator

Bridge and gantry crane operators must have a comprehensive knowledge of the operating capabilities of the crane and be competent to carry out the lifting operation. It is a must for crane operators to:

- know the particular model of crane to be operated, its characteristics, functions and limitations

- know the information in the crane’s operating manual

- ensure loads are evenly balanced and well secured

- hold the appropriate high risk work licence (if applicable) for the type of crane being operated, and complete refresher training as required

- know proper inspection and maintenance procedures to be followed in accordance with the guidelines of the manufacturer and owner

- complete a pre-operational visual inspection and operational check of the crane’s structure and components before each work shift, including inspecting and testing:

- all relevant items indicated in the operations manual

- operating and emergency controls

- brakes.

Lifting materials

Crane-lifted loads should be slung and secured so the load (or any part of it) cannot fall. To ensure the safe lifting of loads:

- General lifting:

- Use lifting hooks with operable safety latches.

- Strap bundled loads (e.g. joists, purlins, scaffold tubes, reinforcement steel, etc) together before lifting.

- Strap timber sheeting together and lifted in a flat position.

- Use tag lines required to control loads.

- Only use basket hitches where there is no risk of people being struck if the basket hitch inadvertently comes off the load (otherwise the lifting sling should be wrapped and choked around the lifted load).

The crane operator should ensure the load is always under control when lowering loads, or when the load is suspended.

Except in an emergency, the crane operator should not leave the cabin or control station on the crane or the remote control while a load is suspended from the crane.

Crane controls

Crane controls should:

- have fail-safe control buttons e.g. constant pressure type

- have function buttons appropriately labelled

- be fitted with a manually reset emergency stop button.

Source: Bridge and Gantry Cranes Information Sheet - Safe Work Australia

Safety devices

Safety devices that can be fitted to bridge and gantry cranes include:

- audible alarms and flashing lights that warn when the crane is moving

- anti-collision devices to prevent:

- a bridge or gantry crane colliding with the end of the runway

- two or more bridge or gantry cranes that operate on the same runway from colliding with each other.

- deceleration devices to slow the bridge or gantry crane down—regardless of what control is being pressed when a travelling crane is approaching the end of the runway—to prevent end stop collision or over run e.g. limit switches and two-stage decelerators

- load-limiting and movement controlling devices to assess the load and prevent lifting should the rating capacity of the crane be exceeded

- upper and lower limit devices to prevent the hoist from winding the hook into the hoist drum or winding the hoist rope off the hoist drum

- anti-fall devices, such as anti-drop plates, to prevent any part of the structure falling if a travel-wheel fails.

Source: Bridge and Gantry Cranes Information Sheet - Safe Work Australia

Signage

The crane classification and working load limit of the crane must be displayed on bridge and gantry cranes.

Source: Bridge and Gantry Cranes Information Sheet - Safe Work Australia

Inspection and maintenance

Routine inspection and maintenance should be carried out in accordance with the manufacturer’s instructions. Bridge and gantry crane inspection and testing must include:

- a major inspection

- regular inspection and testing required for the crane

- inspection and testing for plant item re-registration.

Source: Bridge and Gantry Cranes Information Sheet - Safe Work Australia

A written report should be supplied upon completion of the inspection.

Maintaining the integrity of lifting gear

Check:

- the lifting gear is tagged and all relevant information listed (e.g. information for a chain sling includes grade of chain, working load limit, manufacturer, chain size and Australian Standard marking)

- shackles used as terminal fittings are prevented from unscrewing (e.g. mousing or similar)

- lifting eyes and inserts are compatible and the same proprietary brand

- lifting slings are not damaged (e.g. excessive wear, damaged strands, cracks, chemical attack, deformation or severe corrosion)

- the sling is appropriate for loads being lifted, including adequate capacity and protection from sharp edges

- operable safety latches are fitted to sling hooks.

You must minimise any remaining risk with suitable personal protective equipment, such as hard hats, protective footwear, eye protection, safety vests.

The control measures put in place should be reviewed regularly to make sure they work as planned.

More information

- How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB)

- Managing the risks of plant in the workplace Code of Practice 2021 (PDF, 1.57 MB)

- Mobile crane Code of Practice 2024 (PDF, 2.29 MB)

- Guidance - Cranes

- Information Sheet: Bridge and Gantry Cranes – Safe Work Australia

- Young workers

- Australian Standards: 2550 Cranes, hoists and winches - Safe use Part 3: Bridge, gantry, portal (including container cranes) and jib cranes (subscription required)

- Australian Standards: 1418 Cranes, hoists and winches Part 18: Crane runways and monorails (subscription required)

Support for people affected by a serious workplace incident

For advice and support: