Worker killed in trailer rollover

In September 2023, a worker was killed as material unloading activities took place on a construction project. A dog trailer that was part of a rigid truck and single dog trailer combination, rolled onto its side and pinned the worker underneath.

A dog trailer is commonly a trailer with two axle groups, one at the front and one at the rear, which is steered by the front axle and the connection to the towing vehicle. See Figure 1.

Figure 1: Dog trailer example

Source - Department of Transport and Main Roads

These findings are not yet confirmed, and investigations are continuing into the exact cause.

Safety issues

Managing construction site traffic is a significant safety issue. Construction workplaces have a wide range of vehicles and mobile plant that can seriously injure workers.

Typical hazards can include:

- traffic movements of mobile plant and vehicles - mobile plant and vehicles moving in and around a workplace (reversing, loading, and unloading) are a potential danger for workers and members of the public.

- the environment in which the mobile plant and vehicles are used, and

- the plant itself.

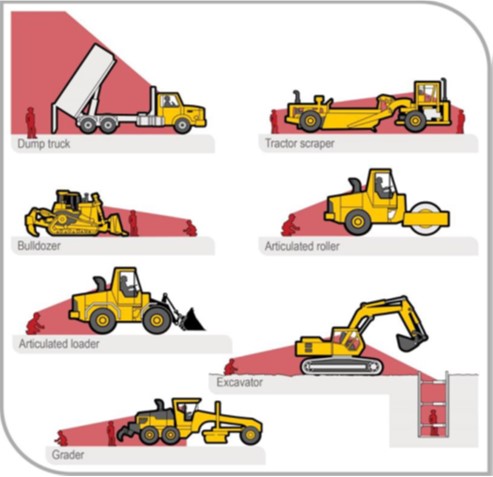

Operators of mobile plant and vehicles can often have severely restricted visibility of ground workers or nearby pedestrians, particularly those close by. See Figure 2 below.

Figure 2: Mobile plant operator blind spots

Ways to manage health and safety

Effective risk management starts with a commitment to health and safety from those who manage the business. If an incident occurs, you'll need to show the regulator that you’ve used an effective risk management process. This responsibility is covered by your primary duty of care in the Work Health and Safety Act 2011.

Use the hierarchy of controls to help decide how to eliminate and reduce risks in your place of work. The hierarchy of controls ranks types of control methods from the highest level of protection and reliability to the lowest. It’s a step-by-step approach to eliminating or reducing risks. You must work through the hierarchy of controls when managing risks, with the aim of eliminating the hazard, which is the most effective control.

Possible control measures to prevent similar incidents

A person conducting a business or undertaking (PCBU) that commissions a construction project is the principal contractor (PC) for that project. A PC is also a PCBU and must also comply with the duties of a PCBU. Each construction project will have a PC who has specific duties under the Work Health and Safety Regulation 2011, in addition to their duties as a PCBU.

The PC and PCBUs are all required to control the risks associated with mobile plant and vehicles, including the risk of pedestrians being struck by vehicles such as trucks.

Before any mobile plant or vehicle is operated, the person with management or control of it must ensure:

- the vehicle selected is right for the task and is fitted with suitable safety features (e.g., rear-view mirrors and reversing warning devices) and provided with a suitable combination of operator protective devices (such as enclosed cabins and seatbelts)

- the design and implementation of a traffic management plan, including identifying areas where pedestrians and mobile plant may be working in close proximity. It may be necessary for some tasks to be limited where there is a risk or workers being hit by mobile plant

- suitable exclusion zones and communicating these to workers and other people in the vicinity before tasks are carried out. Depending on the task being undertaken, additional requirements may need to be implemented (e.g., specified exclusions zones around plant during loading or unloading)

- the use of a spotter where required, including suitable means of communication between the spotter and operator (e.g., two-way radio) to assist with the safe movement of the vehicle, particularly where there may be blind spots or other workers in the vicinity

- the vehicle is fitted with an appropriate warning device to alert people who may be at risk from the movement of the vehicle. Warning devices must be suitable for the site conditions and be tested and maintained in line with the manufacturer’s recommendations. There are several warning devices that can be fitted to mobile vehicles to alert the operator and others in the workplace including:

- automatic audible alarms which are usually fitted to warn people about forward or reversing movements

- motion sensors are used to activate an integrated or separately located alarm. Motion sensors also warn with sound. They are sensitive to movement and are activated by motion in the required direction

- lights are usually used to warn people about forward and reversing movements. These lights are wired to operate continuously or in hazard mode by flashing, usually when reversing

- radio sensing devices activate when the operator selects reverse. A light and alarm sound inside the cabin to alert the operator if a pedestrian is within a predetermined distance from the rear of the plant

- air horns are suitable for powered mobile plant with long braking distances, (i.e., trucks). Some large workplaces or sites may require a truck to 'stop and sound the horn before continuing'.

- the manufacturer's operating instructions have been read and are followed

- workers who operate the vehicle or plant are appropriately licenced and competent or suitably supervised during training. Training programs should be practical and ‘hands on’ and take into account the particular needs of workers like literacy levels, work experience, and specific skills required for the safe use of the vehicle or plant. Training on the make and model of the vehicle or plant should be documented

- that maintenance and inspection of the plant or vehicle is carried out by a competent person in accordance with the manufacturer’s recommendations

- there is adequate lighting to safely operate the vehicle

- any workers around the vehicle are aware of operator blind spots and exclusion zones

- if outdoors, the effect of adverse weather conditions (e.g., reduced visibility) has been considered

- ground conditions and the intended travel pathway have been inspected and assessed to identify any problem areas (e.g., sloping or unstable ground).

- if high risk construction work is planned to be undertaken a safe work method statement (SWMS) must be developed where required

- the best way to protect pedestrians is to ensure people and vehicles cannot interact. This can be achieved by not allowing vehicles into pedestrian spaces or not allowing pedestrians into vehicle operating areas. Determine if the worker can do their job outside of the exclusion zone, at another time, or when the plant is inactive.

However, this may not always be reasonably practicable and where pedestrians and vehicles cannot be separated, using the following should also be considered:

- Use physical barriers that prevent pedestrian or plant access to designated areas, such as fencing, para-webbing or water filled barriers. Witches hats, bollards or bunting are less effective as they do not physically stop someone entering an exclusion zone or roadway.

- Signage should clearly mark pedestrian walkways, guide traffic, provide warnings and identify exclusion zones.

- Supervision of the exclusion area and good communication between the supervisor and plant operator will ensure that access to exclusion zones is limited to authorised personnel. Identify when workers and visitors will be on site and the areas they will need to access.

- Where possible, have separate entry points for plant and pedestrians and clearly separate pedestrian walkways.

Traffic Management

A traffic management plan documents and helps explain how risks will be managed at the construction workplace. Consultation with workers may involve providing information about the plan as well as the procedure that will be implemented for monitoring and reviewing it over the course of the project. Everyone affected by the plan must understand it and follow it.

An effective traffic management plan will include broad types of control measures that aim to:

- keep vehicles and people apart

- limit vehicle movements or speed

- avoid the need for reversing vehicles

- provide clear signage road/area markings

- ensure effective workplace communication.

The traffic management plan should be monitored and reviewed regularly including after an incident to ensure it is effective and takes into account changes at the workplace.

Source: Traffic management: Guide for construction work – Safe Work Australia.

Any remaining risk must be minimised with suitable personal protective equipment. For example: hard hats, steel cap boots, and high visibility vests.

Administrative control measures and PPE rely on human behaviour and supervision. If used on their own, they are least effective in minimising risks. The control measures you put in place should be reviewed regularly to make sure they work as planned.

Further information

- Managing the risks of plant in the workplace code of practice 2021 (PDF, 1.57 MB)

- How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB)

- Video: Working in and around mobile plant

- Mobile plant

- Guide: Safe Work Method Statements

- Work health and safety consultation, co-operation and co-ordination Code of Practice 2021 (PDF, 0.54 MB)

- Traffic management for construction or maintenance work code of practice 2008 (PDF, 0.8 MB)

- Traffic management: Guide for construction work – Safe Work Australia.

Support for people affected by a serious workplace incident

For advice and support: