Elevating work platform overturned due to damaged wiring

Issued: 29 October 2007

Background

A "SNORKEL" mobile Elevating Work Platform (EWP) (photo 1) utilises hydraulic legs on each corner for stability. Deployment of the hydraulic legs is controlled by a levelling circuit. These legs can be raised and lowered from the operator platform when the platform height is below two meters. When the operator platform is elevated above two meters, the hydraulic levelling circuit is automatically locked.

This EWP sustained damage to the wiring harness connecting the controls on the operator platform to the base of the machine. The wiring harness is clipped to the scissor elements and is susceptible to movement when raising and lowering the platform. During maintenance, an unlined non-standard metal clip with mini serrations on its edges was fitted to the machine to replace a standard clip. Damage to the wiring insulation resulted, causing the 12 volt power supply to earth. This led to one outrigger extending, tipping the EWP over and causing the operator's death.

Problem

The raising and lowering of the operator platform caused the wiring harness to move through this clip, cutting insulation from the wires and leading to intermittent earthing of the voltage supply to the electro-hydraulic valves on the levelling circuit. The intermittent earthing resulted in erratic behaviour of the stabiliser legs with the platform fully raised. The machine overturned when one stabiliser leg fully extended.

Aggravating factors

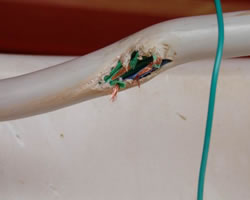

The wiring harness clips usually have a rubber layer between the metal and the wire insulation (photo 2). This rubber insulation was found to be missing where the wiring harness wires were chaffed (photos 3 and 4).

Photo1. SR27770 EWP |  Photo 2. Clip with rubber lining |

Photo 3. Control wires damaged by chaffing |

Photo 4. Clip that caused chaffing |

Recommended control measure

Owners of these machines are to ensure the wiring harness wire is protected from damage during raising and lowering of the platform.

As a response to the incident, Snorkel international have designed a modification to the wiring to deactivate the automatic levelling circuit when the platform is above two meters. Service bulletin NZ SB139 details these modifications.

Contact : Snorkel International 02 9725 4000

General

Employers have a duty to ensure workers are aware of this risk and to implement controls to prevent or minimise the risk.

Employers also have a duty to ensure maintenance of plant is carried out to minimise risk.

Legislative requirements

The information contained in this Alert is designed to help persons meet their duties regarding the management of risks associated with the use of EWP's. The Managing the Risk of Plant in the Workplace Code of Practice 2021 (PDF, 1.57 MB) identifies the AS 1418 series of Australian Standards. AS 1418.1 and AS 1418.10 are included within this series as design standards applicable for EWP's.