Truck mounted forklifts

Issued: 4 July 2007

Purpose

To alert all persons conducting a business or undertaking (whether as employer, self-employed person or worker), of the risk of failure of the "top mounting kit" when loading or unloading a Manitou forklift to and from the tray of trucks or trailers.

Background

A recent incident has occurred in Queensland when the loading mechanism failed while unloading a Manitou forklifts from a trailer. Figure 1 shows an example of the sequence of events during the incident. The operator received serious head and upper body injuries.

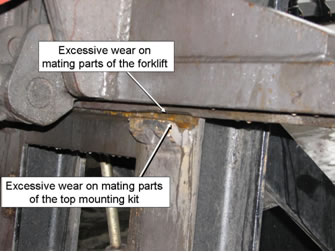

Initial investigations have revealed excessive wear to the mating sections of the loading mechanism. This has affected the effectiveness of the mechanism to hold the forklift in place during the unloading process. Figure 2 shows an example of excessive wear on the mating parts of the loading mechanism.

Fig 1 – Incident when unloading Manitou forklift from a truck

Inspection

A competent person must be engaged to inspect the loading assembly for truck mounted forklifts in accordance with the manufacturer's instructions. This is to ensure the loading mechanism and fork lift mounting plate are not excessively worn. An inspection report should be provided to the owner of the equipment. The physical dimensions and acceptable tolerances to be used for the inspection can be obtained from the Australian agent for Manitou, NTP Forklifts Australia.

Fig 2 – Photograph showing excessive wear on the mating parts of the loading mechanism

Repairs

Where an inspection has identified excessive wear on mating parts of the loading mechanism, the equipment must be repaired and faulty parts replaced to ensure the loading mechanism operates effectively.

The forklift operator should make sure the forklift is securely fastened to the truck during transportation. This will minimise vibration between the forklift and the truck platform which can result in excessive wear on the locking mechanism that secures the forklift during loading and unloading.