Obligations for guardrail systems

Issued: 1 April 2008

Last updated: April 2008

Background

Guardrail systems may be an effective way to manage some of the risks of working at heights.

The effectiveness of a guardrail system depends on:

- appropriate design

- manufacture in accordance with the designer's specifications

- test and examination after manufacture

- instructions supporting use and maintenance of the system

- correct installation by a competent person

- appropriate use.

Designers, manufacturers, suppliers and installers all have obligations for the guardrail system that is supplied. Users of the system, including the principal contractor, employers, self-employed persons and workers also have obligations for how it is used and maintained.

View advice for obligation holders

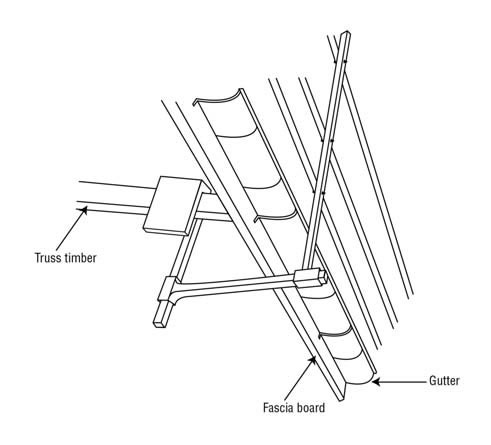

The principles outlined here apply to guardrails attached directly to roof trusses, attached to hanging bracket systems (stud brackets) and other guardrail systems.

Health and safety obligations

Control measures, such as a guardrail system, must be used under the law for:

- housing construction work where there is a potential for a person to fall more than 3 metres; or

- other construction work where there is a potential for a person to fall more than 2 metres; or

- construction work on a roof, or partly completed roof surface with a slope not over 26°.

This includes gable ends and porticos.

There are requirements for edge protection used in construction. These requirements include:

- a bottom rail fitted at least 150mm but not over 250mm higher than the surface that is at the base of the edge protection; or

- a toe board, for the surface that is at the base of the edge protection, at least 150mm high and fitted below all rails of the edge protection; or

- if the slope of the surface from which work is to be done is over 26° - sturdy mesh, sheeting or other material that extends upwards at least 900mm from the surface that is at the base of the edge protection or toe board.

In this section, toe board for a surface means an upright timber or metal board securely fixed in place at an edge of the surface.

Advice for obligation holders

A designer of a guardrail system has an obligation to ensure that:

- the system is designed to be safe and without risks to health when used properly; and

- the design, if given to someone else to use, is accompanied by information about the way the plant must be used to ensure health and safety.

The designer should consider:

- the type of structures the system may be attached to; and

- the loads that may be applied if a worker falls against the guardrails.

The Australian Standard AS/NZS4994 (Int) Temporary Roof Edge Protection for Housing and Residential Buildings provides guidance on the testing of roof guardrail systems.

The Australian Standard AS/NZS1657 Fixed Platforms, Walkways, Stairways and Ladders – Design, Construction and Installation provides guidance on design loadings for permanent guardrailing.

The manufacturer of a roof guardrail system has obligations to ensure that:

- the system is manufactured to be safe and without risk to health when used properly;

- the system, when manufactured, is tested and examined to ensure it will be safe and without risk to health when used properly; and

- the system, when supplied to another person, is accompanied by information about the way it must be used to ensure the health and safety of users.

A supplier of a guardrail system has an obligation to either:

- examine and test the system to ensure it is safe and without risk to health when used properly; or

- ensure the manufacturer has given an assurance that the system has been examined and tested to ensure it is safe and without risk to health and safety when used properly.

The supplier also has an obligation to provide information about how the system must be used to ensure health and safety.

The supplier should provide installation instructions to the installer, including the following as a minimum:

- details about the supporting structure - member sizes, material type and strength;

- maximum guardrail post spacing; and

- connector details (i.e. bolting, screwing or clamping method).

The supplier should obtain information from the truss supplier about stiffening required to withstand additional loads.

An installer of a guardrail system has obligations to:

- install the system in a way that is safe and without risk to health; and

- ensure that nothing about the way the system was installed makes it unsafe and a risk to health when used properly.

To meet these obligations, the installer of the system should:

- ensure they have the appropriate competencies (through training, qualification and/or experience) to install the system;

- follow the manufacturer's and/or supplier's instructions;

- provide written verification about the system at handover to the person being supplied the system; and

- ensure the Work Method Statement is completed where applicable and given to the principal contractor before installation work commences.

Handover information should include written verification that:

- the guardrail system and supporting structure are structurally adequate (eg. verification by a suitably qualified engineer); and

- the guardrail system has been installed in accordance with the supplier's instructions.

Examples of handover information that should be used are:

- an engineer's written verification (PDF, 0.35 MB)

- an installation checklist (PDF, 0.09 MB) completed by the installer

A person being supplied with the system, such as a principal contractor, employer or self-employed person, has obligations to ensure health and safety in the workplace. They should take reasonable steps to ensure the guardrail system can be used safely.

To meet these obligations, a person being supplied a guardrail system can:

- obtain the verification about the system from the installer;

- have written information on verification of the system available on site – this should be enclosed in a protective plastic envelope attached to the guardrail system so that all users can see that the system has been verified as safe to use; and

- provide users of the system with the advice received from the installer on the safe use of the system – this should be in the instructions in a Work Method Statement, or provided in site rules set out in the Construction Safety Plan (where one is required).

A user of a roof guardrail system, such as an employer, self-employed person or worker has an obligation to comply with the instructions provided about the safe use of the system, and not to interfere with or misuse the system.

To meet this obligation, a user should not alter or change the system in any way that may affect the safety of users of the system. The user should also notify their employer or the principal contractor if the system is altered or damaged in any way.

Further information

Working at heights in the building and construction industry