Industrial rope access safety

Issued: 11 November 2013

Last Updated: 11 November 2013

Purpose

The purpose of this alert is to highlight the risks associated with industrial rope access, particularly the methods used to clean the exterior windows of multi-story buildings.

Background

Two serious incidents occurred on the Gold Coast due to the incorrect selection and use of rope access systems.

In one incident the working line was severed and the worker fell several floors before the rope grab on the second (safety) line locked onto the rope. As the worker fell he repeatedly struck the building and was injured.

In the other incident the worker was injured when he swung down and along the return face of a building due to the pendulum effect.

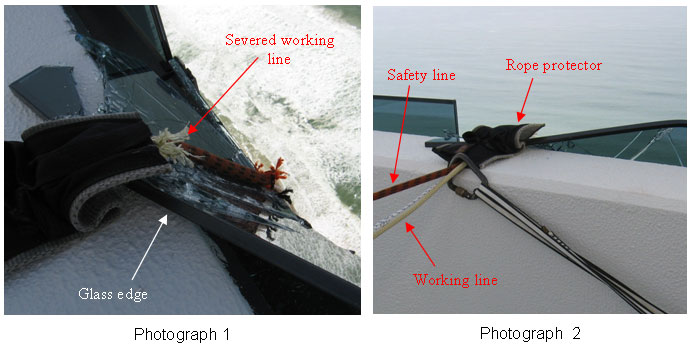

Diagram 1: Some of the components of an industrial rope access system.

Contributing factors

Rope failure incident

In this incident the working line and safety line were set up to pass over the top of a glass balustrade. The glass panel broke, cutting the working line and partially cutting the safety line. It appears the load from the ropes initially caused the glass panel to break and the fractured glass pieces then cut the ropes. As the rope was under tension from the weight of the suspended worker, it was easily cut by the glass.

Photographs 1 and 2 show the working line and safety line passing over the top of a glass balustrade following the incident. It is not known why the rope grab device on the safety line did not immediately lock on the rope but allowed the worker to fall a considerable distance before his fall was arrested.

Pendulum incident

In this incident the worker was using an incorrect set up and was not working directly below the anchor point. Instead he was standing on a ledge of the building while still connected to his suspension system and then moved a horizontal distance away from the original vertical path of the suspension lines. It appears the worker then fell, a pendulum effect occurred, and he swung back across and down the return face of the building approximately 15 metres before hitting a window on a balcony.

Action required

Before commencing industrial rope access work ensure that:

- workers are provided with appropriate instruction, training and supervision

- working and safety lines are never allowed to pass over glass panels or other potentially sharp edges. Where the working and safety lines have to pass over any edge, ensure effective protection is provided to prevent any damage to the lines

- the anchor plan and instructions for use are referenced prior to conducting a risk assessment for the activity. Also ensure any structures are capable of safely withstanding shock loading

- a work method statement is developed and:

- existing anchor points are certified and have been inspected and tested within the last 12 months

- there is suitable signage at each anchor point and at other suitable locations (i.e. at the access door to the roof)

- any structure used as anchoring is capable and has been certified for design loadings specified for industrial rope access systems (refer AS/NZS 4488)

- if the suspension lines pass over a parapet, balustrades or any other structure, these have adequate strength to safely withstand potential loading

- the rope grab device is fit for purpose before use. This includes ensuring the rope grabs will effectively lock on safety lines in emergency situations and the likelihood of the grab being inadvertently held open is minimised (i.e. due to panic or the rope grab becoming tangled)

- operators are competent to perform industrial rope access work

- a minimum of two competent workers are on site

- a rescue plan is developed and tested within the last 12 month

- appropriate records are kept.

Further information

Further information may be obtained from the following:

- How to manage work health and safety risks Code of Practice 2021 (PDF, 0.65 MB)

- Managing the risks of plant in the workplace Code of Practice 2021 (PDF, 1.57 MB)

- The Australian Rope Access Association (ARAA) (provides guidance on the safe use of rope access systems)

Further information may be obtained from the following standards:

- AS/NZS 4488.1: Industrial rope access systems: Part 1: Specifications

- AS/NZS 4488.2: Industrial rope access systems, Part 2: Selection, use and maintenance

- ISO 22846.1: Personal equipment for protection against falls - Rope access systems - Part 1: Fundamental principles for a system of work

- ISO 22846.2: Personal equipment for protection against falls - Rope access systems - Part 2: Code of practice