Stair module failures on scaffolding

Published: 12 November 2015

Updated: 3 August 2018

Purpose

The purpose of this safety alert is to highlight the potential risks associated with stair module failures and to provide guidance on ways to minimise the risk of this occurring.

Photograph 1: Single width aluminium stair module after one incident

Background

A number of incidents have occurred in Queensland where modular scaffolding stair units have dropped or stair treads have failed.

In one incident, several welds at one end of a single stair module failed when a worker stepped onto the landing. The top of the landing peeled away causing the stair module to drop off the supporting transom. As the worker fell, his hand was caught on the V-pressing of a standard and a finger was torn off. Photograph 1 shows the stair module after the incident. Photograph 2 shows part of the module that peeled away when the worker stepped onto it.

In a different incident, one section of a double width module stair access dropped off the supporting transoms when a worker stepped onto it. The worker fell to the level below and was injured. In this incident the supporting scaffolding was 'out of square' and the stair module did not sit far enough on one of the supporting transoms.

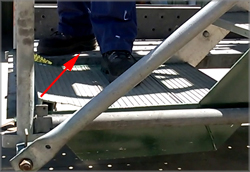

Photograph 2: Aluminium deck peeled away (as indicated by arrow) when a worker stepped onto it and the stairs dropped.

Contributing factors

There are a number of factors that contribute to the risk of stair modules falling off the supporting transoms, including the following:

- Inadequate support provided by the scaffolding transoms underneath both ends of the stair module, for the width of the module. In other words, the gap between the end of the module and the vertical face of the transom is too big (see Photograph 4) – often caused by the stair module being too short or the scaffolding not being square.

- Insufficient welds being located at critical points of the stair modules – often due to 'tack' welds being used instead of continuous or stitch welds (see Photograph 3).

- Stair modules, including welds, being damaged or cracked – particularly during assembly, dismantling and transport.

- The supporting transoms underneath the stair module being able to twist or rotate – possibly due to loose connections.

Photograph 3: Underside view of failed module welds (shown by arrows). | |

Photograph 4: Excessive gap on transom (indicated by arrows). |  Photograph 5:The gap between the vertical face of the transom and end of stairs should not exceed 15 millimetres (unless otherwise specified by scaffolding manufacturer). |

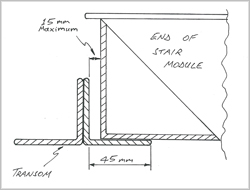

Diagram (a): Sectional view through transom showing maximum gap of 15 millimetres. | |

Action required

1. Adequate transom support underneath stair module

The Scaffolding Code of Practice 2009 provides guidance about scaffolding stairs in Section 4.3 as follows:

- Stairs should be secured to the scaffold bay. If not secured, the supplier should provide documentation illustrating the maximum amount of clearance allowed between the transom and the top and bottom of the stair module.

- Ensure the gap between the end of a stair module and a transom is as small as practicable. Large gaps can lead to stairs dislodging and falling when a load is placed onto it.

All modular stair units are to be adequately supported by scaffolding transoms at both ends of the module, with the module being pushed hard up against one of the transoms (i.e. so that there is no gap at one end). The maximum allowable gap between the vertical part of the transom and the end of the stair module is not to exceed the manufacturer's specifications. As an indicator, the maximum gap between the stair module and the vertical edge of the transom should not be greater than 15 millimetres, unless otherwise specified by the scaffolding manufacturer. This maximum gap is based on the following:

- an additional lock system is not provided (examples are shown in Photographs 6 to 10)

- the gap is measured at one end of the stair module with the module pushed up hard against the opposite transom

- the gap does not exceed 15 millimetres, anywhere along the length of the supporting transom. Refer to Diagram (a) and Photograph 5

- transoms with a horizontal width of at least 45 millimetres are used.

2. Structural integrity of stair module

Stair modules should be strong enough to withstand the loads applied during use, installation and transport. Tack welds should be avoided as they are more prone to cracking and failure. Welds should be continuous or stitch type welds.

The stairs should be inspected before:

- being sent to site

- the scaffolding is signed off for use.

The inspection process should include the following:

- Checking the stair modules are the correct ones to use on the scaffolding in question.

- Inspecting all welds for any visual defects including cracks and undercuts in the welds.

- Identifying and removing units that have welds or components different from the design.

- Inspecting the modules for straightness, damage and excessive wear.

3. Additional locking systems to prevent modules dislodging

Some scaffolding manufacturers and suppliers provide additional locking systems on the stair modules to help prevent the modules dislodging. These systems include hooks that pass over the top of the transom, a prop under the stair module and clamping systems. Photographs 6 to 10 show four different examples of locking systems used by some scaffolding suppliers in Queensland. While these systems do not have to be used on all stair modules, they are to be used wherever the scaffolding manufacturer or supplier approves and specifies their use.

The use of additional locking systems does not remove the need for adequate transom support under the modules.

Photograph 6: Lock hooks over transom. |  Photograph 7: Close up of hook. |

Photograph 8: Prop underneath stair module. |  Photograph 9: Horizontal tube under stretcher stairs. |

Photograph 10: Clamp securing stair module to transom. | |

General risk control measures for scaffolding

- All scaffolding is to be erected by a suitably qualified person. Where the height of the working platform is four metres or higher, the person erecting the scaffolding must hold the relevant high risk work licence as a scaffolder.

- Components used for the assembly of the stair system should be compatible with the scaffolding system being used.

- All scaffolding should be inspected at minimum intervals of at least every 30 days.

- The supporting scaffolding should be built to the manufacturer's specifications - each scaffolding bay needs to be square.

- Double width stair halves should be secured together with proprietary system bolts as recommended by the manufacturer.

Further information

Further information can be obtained from the following:

- Scaffolding Code of Practice 2021 (PDF, 1.63 MB)

- Australian New Zealand Standard AS/NZ 1576: Scaffolding.