Failures of concrete pump delivery pipeline end fittings and hoses

Issued: 15/04/2021

Last Updated: 20/04/2021

Purpose

This safety alert highlights the risk of failure of concrete pump delivery lines including failures of end fittings.

Businesses that fit end fittings to concrete delivery hoses and pipes should follow and document sound engineering practices and provide information on inspection methods to customers.

Concrete pump owners should obtain information from suppliers of pipes and hoses on the manufacturing methods used and appropriate inspection methods.

Background

There have been incidents in Queensland where delivery lines have failed and sprayed concrete under pressure.

Failures included a:

- rubber delivery hose failure

- coupling stem cracking with the end breaking away (refer Photograph 1)

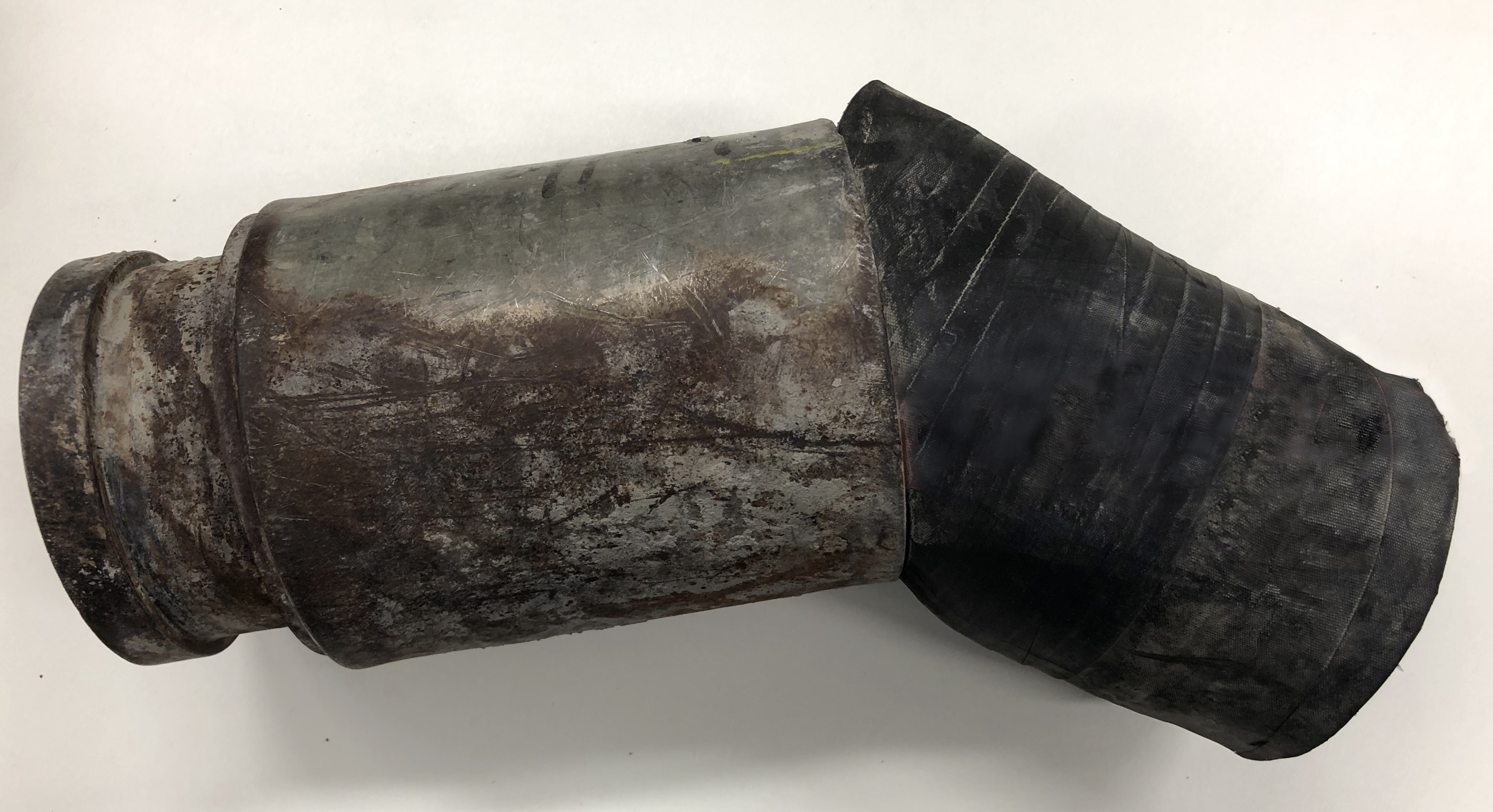

- end fitting starting to separate from the rubber hose (refer Photograph 2) with the concrete spraying out of the gap

- flange cracking and breaking away from a steel 90-degree, 6-inch to 5-inch reducer bend, located at the hopper (refer Photographs 3 and 4).

Concrete pumping pressure can be in excess of 85 bar, especially when blockages occur. All of these incidents had the potential for serious injuries if workers had been near to where the failure occurred. In one incident, a car’s windscreen was broken approximately 15 metres away.

Photograph 1: Cracked and failed part of a hose stem.

Photograph 2: Swaged end fitting that has separated from the hose.

Photograph 3: Failed flange on steel reducer bend.

Photograph 4: Location of steel reducer bend.

Contributing factors

Hoses and end fittings can fail due to:

- the pressure rating of the concrete pump exceeding that of the rubber hose or end fittings

- incorrect tolerances on the inner and outer parts of the coupling

- the swaging or crimping procedure does not comply with the manufacturer’s specifications

- incorrect specifications for the rubber hose

- excessive wear—especially on the internal part of the fitting from concrete flow.

Flanges on steel pipes can fail due to:

- poor welding due to incorrect electrodes, incorrect preparation, lack of penetration, or other welding irregularities

- flanges and pipes being made from steel types that can be difficult to weld

- poor matching of flanges to pipes (i.e. the flange doesn’t fit well on the pipe end)

- mishandling of the pipe flange (i.e. bashing the flange or pipe with a hammer when the adjacent pipe and/or hose clamp isn’t aligned)

- poorly fitting hose clamps (e.g. incorrect size, concrete build up).

Action required

Concrete pump owners

Concrete pump owners need to ensure that the pressure rating of the concrete pump does not exceed that of the pipeline. For example, if a pump is rated at 85 Bar concrete pressure then it is unacceptable for steel pipeline to be replaced with rubber hose with a maximum rating of 45 Bar. Owners must also take reasonable steps to ensure that a quality assurance program is followed while attaching the end fittings so that failure of the end fittings is avoided. It is generally easier to obtain certification from a local supplier when purchasing equipment.

If a concrete pump owner imports components from overseas, it may be more difficult to obtain trustworthy information on the manufacturing process. This is the case when the overseas supplier is unknown or there is no manufacturer's mark. Unscrupulous manufacturers have also been known to copy manufacturers' names and trademarks, so marking of products alone may not provide adequate evidence that the product is fit for purpose.

A concrete pump owner who imports equipment from overseas takes on the duties of an importer under the Work Health and Safety Act 2011 (WHS Act). The importer must carry out, or arrange to have carried out, any calculations, analysis, testing, or examination of the equipment to control safety risks.

Suppliers of pipes and hoses

Suppliers of hoses and pipes with end fittings should ensure a quality assurance program is followed while attaching the end fittings and that information on this program is available for the purchaser.

Suppliers should also provide documented instructions on the operating parameters of the product along with inspection methods to be used.

If the supplier attaches end fittings to pipes or hoses, the supplier takes on the duties for manufacturers under the WHS Act in addition to those duties for suppliers.

Fitting end fittings to hoses

End fittings are attached to rubber hoses using two methods, crimping and swaging. With the crimping method, compressive forces are applied radially to the outside part (ferrule) of the end fitting with the inner stem inserted inside the end of the hose. A crimped end fitting can be clearly recognised by obvious indentations on the outside of the end fitting (refer Photograph 5). With the swaging method, the end fitting is attached to the hose when the end fitting is pushed onto the end of the hose under hydraulic pressure. Although there will be some marking on the end fitting from the manufacturing process, swaged end fittings do not have obvious indentations like a crimped end fitting. Photograph 2 is an example of a swaged end fitting that is partly separated from the hose.

Although crimping and swaging are fundamentally different, both methods rely heavily on using quality components of the correct tolerances along with ensuring a stringent process for attaching the end fittings is followed.

Hose manufacturers will typically only certify that their hose is capable of withstanding specified concrete pressures when high quality hose ends are fitted. Some hose manufacturers operate under the concept of a matched pair where they will only guarantee their hose for a maximum pressure, when end fittings from a particular manufacturer using a verifiable crimping or swaging method are used.

Photograph 5 – Crimped end fitting clearly showing crimping indentations.

When assembling end fittings on hoses ensure:

- compliance with all of the conditions specified by the hose and/or end fitting manufacturer

- the hose material and dimensions are suitable for concrete pumping and for fitting of the specific type of end fitting

- the size of the external and internal parts of the fitting must be within the tolerances specified by the hose manufacturer or fitting manufacturer for the dimensions of the hose used

- the method of attaching the end fitting must comply with the specifications of the manufacturer (information from the hose manufacturer may also be needed).

Testing of the end fitting is one way to help demonstrate the integrity of the connection. Proof testing of all fittings or destructive testing of samples are methods that can be used. If proof testing is carried out, the test method needs to ensure the fitting and hose are not damaged.

Following attachment of the end fitting to the hose, the fitting should be permanently marked with information on the batch number and an identification mark of the company attaching the end fitting. This will assist with traceability and authentication of the assembly procedure. The method of marking must not adversely affect the integrity of the hose assembly.

If there is any doubt about the manufacturing criteria or testing relating to the end fitting, the advice of the original equipment manufacturer (OEM) should be obtained. If this is unavailable, the advice of a suitably qualified professional engineer should be obtained.

Documented information on the method of attaching the end fitting should be maintained by the business attaching the end fitting and should be available on request.

Welding flanges to steel pipe

Welding flanges to steel piping used for concrete pumping is a complex issue and requires high levels of technical input and skill to ensure the welding process will result in a quality product.

The following should be ensured:

- Only pipe specifically intended for concrete pumping should be used. Prior to welding, there should be some reliable method of verifying that the pipe and flanges are the actual type ordered.

- The weld specifications are to be compatible for the pipe and flange material characteristics and pressure specifications of the pipe being welded. Information should be obtained from the pipe manufacturer on this issue.

- Welding should be in accordance with a detailed weld procedure that includes electrode selection, pre-heating instructions (where required) and the use of a welding method that is recommended by the pipe manufacturer.

- Carrying out destructive testing on a test sample to verify the welding method is fit for purpose.

Inspection of hoses and pipes

Owners and operators of concrete pumping equipment need to ensure ongoing inspection of pipes and hoses is carried out. Inspection methods and intervals for measuring pipe thickness are outlined in the Concrete Pumping Code of Practice 2019 (PDF, 1.04 MB). However, in addition, an inspection program should be applied to end fittings on rubber hoses and flanges on steel pipes.

Inspection of hoses

Documented information on inspection of hoses (i.e. from the OEM), should be provided by the business who fits the end fitting and this should be passed on by the hose supplier to the end user.

The inspection program should include an inspection before use and a periodical inspection with the interval based on the frequency of use and the operating environment.

The inspection program should include:

- an internal inspection with sufficient light levels checking hose tubes are of reasonable thickness, there is no textile fabric or steel reinforcing exposed, there are no blockages, rips, cuts or tears of the liner tube, and there are no collapsed sections of the inner tube or hose

- an external inspection checking for cover damage including cuts, tears, abrasion exposing the reinforcing material, chemical attack, kinks or collapsed areas, soft spots, cracking or weathering

- inspection of end fittings for excessive wear and thinning of the wall thickness

- visual inspection of end fittings for cracks. If there’s any doubt or there is a history of cracking, non-destructive examination may be required

- checking end fittings are intact and not slipping from the hose due to old age or from mechanical pulling loads.

Inspecting welded flanges on steel pipe

In addition to thickness testing of steel pipeline (specified in the Code of practice) and checking the pipeline for damage, it is important to check flanges on concrete pumping pipe.

The inspection program should include inspection of:

- welds for cracks, missing weld, weld undercut and weld consistency

- flanges to check they are not deformed and do not have hammer marks

- pipe ends internally for uneven wear and cracking

- flanges to ensure they are free from concrete build-up and other foreign material.