Preventing injuries in poultry processing

Recent research has found that an integrated, systems-based approach to injury prevention can provide many benefits to preventing injuries in the poultry processing industry. Conducted by Workplace Health and Safety Queensland (WHSQ) and the University of Queensland (UQ), the research identified a number of outcomes from implementing an early intervention program along with injury prevention and workplace injury management strategies.

Recent findings on safety

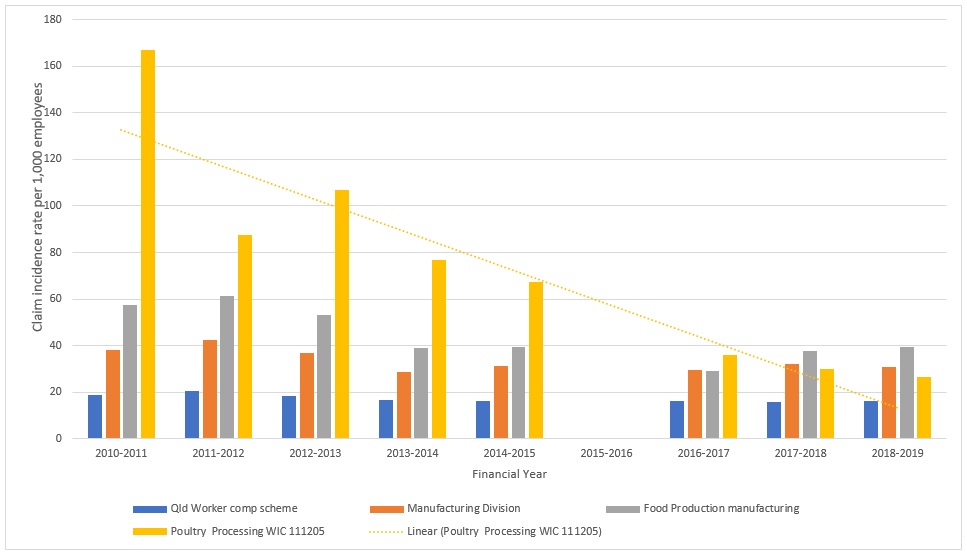

- The rate of time-lost compensation claims in poultry processing is nearly double the Queensland average, despite recent improvements, and the industry’s compensation premiums are three times the state average – see Figure 1 - Workers' compensation claim incidence for time lost claims: 2010 to 2019.

- The most common safety issues identified were related to electrical safety, hazardous chemicals and hazardous manual tasks that contribute to musculoskeletal disorders (MSD).

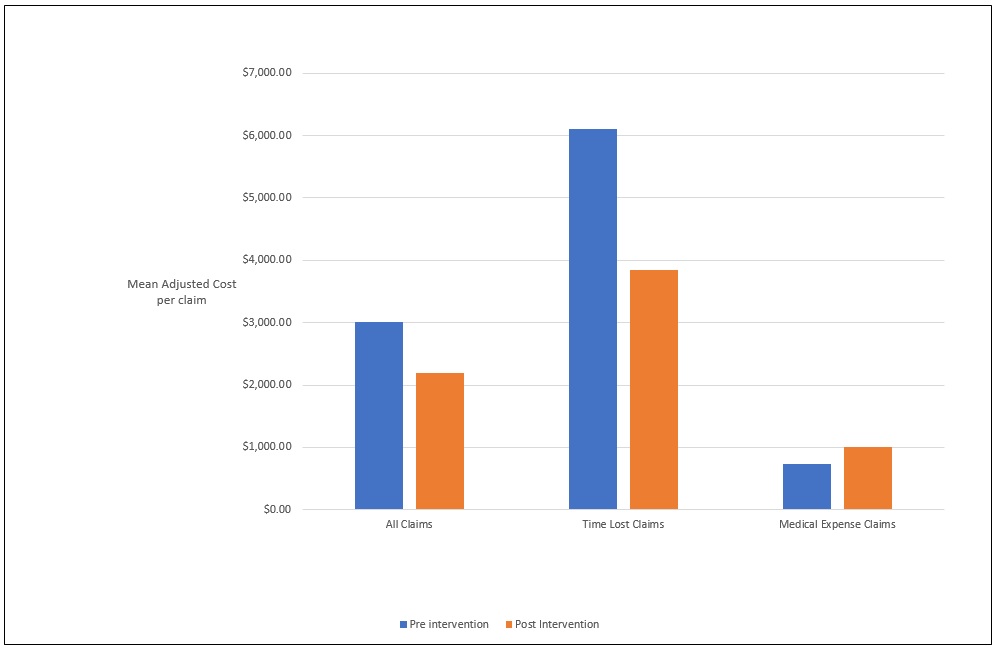

- Integrated, evidence-based measures for injury prevention and management can result in a significant reduction in compensation and average costs per claim, and fewer lost time injury claims. Figure 2 - Adjusted mean musculoskeletal claim costs before and after intervention.

- Work areas with good attitudes toward safety and disability management see fewer injuries, less claims and more positive return to work outcomes.

Research into injury prevention in the poultry processing industry

In a collaboration between Workplace Health and Safety Queensland and the University of Queensland (UQ), research was conducted into identifying the benefits of an integrated, systems-based approach to injury prevention, early intervention, and how employers can enhance safety and productivity in the poultry processing industry.

UQ researchers worked with a poultry processing plant on injury prevention and disability management.The program focussed on systems and processes that encourage workers to report safety concerns and symptoms early and without retribution. The research also looked at the effects of workplace culture, disability management and labour management on work injury and disability.

The research used an onsite injury prevention team, including supervisors, trainers, first aid officers, OHS officers, and workplace rehabilitation and return to work coordinators. It also included a contracted allied health professional (in this case a physiotherapist with skills in occupational health for the two years of the study and two and a half years after the study).

UQ also investigated how attitudes towards safety, disability management and labour management within the organisation affected rates of work injury and disability. Researchers surveyed workers with questions about the organisation’s:

- culture relating to people

- culture relating to safety

- disability management practices

- labour management practices

Research outcomes and findings

- Following the two-year early intervention program there was a:

- 18 per cent reduction in workers’ compensation claims

- 27 per cent reduction in adjusted mean costs per claim

- 37 per cent reduction in median days lost from work injury.

- Interventions were particularly effective for musculoskeletal injuries, sprains and strains (which make up a significant proportion of injuries in this industry).

- Once the benefits were established, removing the contracted physiotherapist had no significant impact on the outcomes.

- Injury was strongly associated with poor safety climate, disability management and labour management practices.

- Work areas reporting a better safety climate, and stronger disability management and labour management practices were associated with lower rates of work injury and shorter work absences than those areas with poorer measures.

- When safety climate scores increased by 20 per cent, the rate of work injury reduced by 43 per cent.

- Variations between different work areas and shifts indicate that ‘microclimates’ may exist within a single organisation.

Injury prevention strategies

- Encourage workers to report any safety concerns either directly to their supervisor, or through their safety representative.

- Investigate safety concerns through safety audits, ergonomic assessments or risk assessments.

- Open communication between workers and supervisors is encouraged, including regular safety talks.

- Ergonomic systems should be embedded in the workplace. For example:

- manual handling minimised where possible (e.g. using conveyor belts, electric pallet jacks, scissor pallet lifts, adjustable height stands and cones)

- automated processes used where practicable (e.g. thigh deboning)

- centralised knife sharpening system introduced with regular training

- regular knife sharpness testing program implemented.

- Establish reporting systems to track issues, injuries and near misses and establish trends (e.g. variations between different shift times and work zones).

- Train all staff on safe work practices and manual tasks using ‘on the floor’ trainers.

- Streamline supervision both within and across work-zones (e.g. coordinated supervision across thigh boning, trimming and packing).

- Implement task rotation for greater job diversity and less continuous knife work (e.g. rotating from breast de-boning to breast packing, trimming and inspection).

- Implement short but frequent stretch breaks (e.g. two-minutes every 30 to 45 minutes), with exercises targeted at high-risk body areas (e.g. upper limbs for processing, lower back and legs for freezer and despatch work).

- If utilising labour hire, ensure compliance with the Labour Hire Licensing Act 2017 and integrate labour hire considerations into health and safety matters.

Workplace injury management strategies

- Implement early intervention and prevention strategies to minimise the likelihood of a small issue developing into a costly compensable claim

- Encourage workers to immediately report early onset of MSD issues, even before an injury has occurred (e.g. muscular fatigue or soreness) to supervisor, trainer or first aid officer, without risk of reprisal.

- Establish reporting systems to log and monitor issues and trends.

- Investigate issues early through collaborations between the worker, supervisor and onsite disability management supports (for example first aider, rehabilitation coordinator or onsite allied health professional trained in occupational health and work injury management).

- Include the worker in identifying the most appropriate management process, which could include:

- staying at work on mutually agreed alternative or modified work tasks

- trialling self-management injury prevention exercises (closely monitored)

- referral to workplace trainer for review of knife skills particularly sharpening

- referral to OHS team for full ergonomic assessment of work task

- referral to an allied health professional for assessment and/or management

- seeking offsite medical advice and management if required or requested.

- Review worker’s progress regularly and if not improving, seek further opinion.

- Upskill and train supervisors, workplace trainers and first aid officers in triage, injury management and return to work processes. Utilise these skilled workers within a collaborative workplace Injury Prevention Team (IPT).

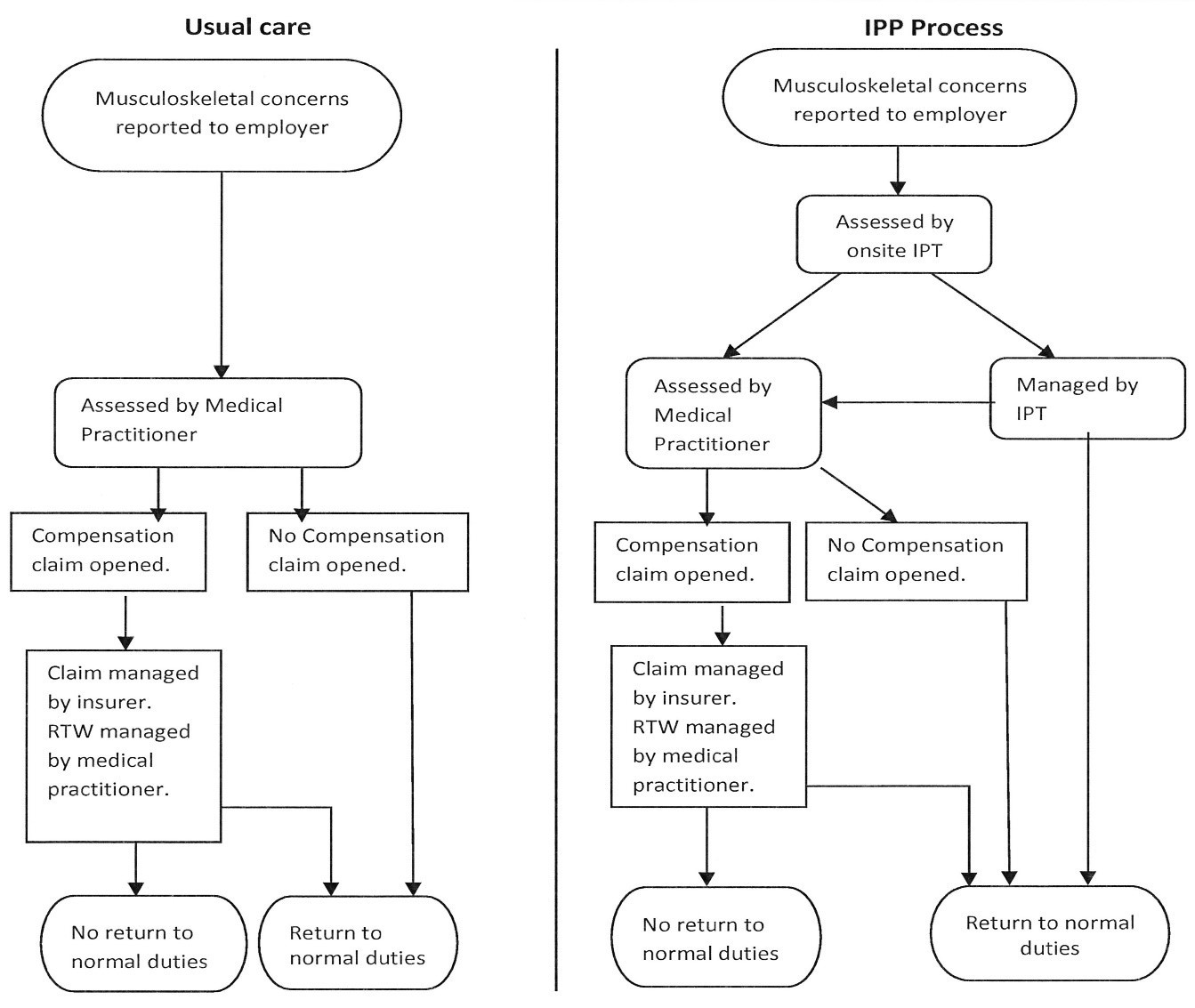

- Figure 3 - Flowchart of early intervention program outlines the process of an early intervention program where an onsite IPT was able to contribute to significant improvement in compensation outcomes.

Related links

- The effect of a workplace-based early intervention program on work-related musculoskeletal compensation outcomes at a poultry meat processing plant

- Exploring associations of employee reports on safety climate, disability management and labour management with work characteristics and injury at an Australian poultry meat processing plant

Figure 1 - Workers' compensation claim incidence for time lost claims: 2010-2019

Figure 2 - Adjusted mean musculo-skeletal claim costs before and after intervention

Reprinted by permission from Springer Nature. Journal of Occupational Rehabilitation. The Effect of a Workplace-Based Early Intervention Program on Work-Related Musculoskeletal Compensation Outcomes at a Poultry Meat Processing Plant. Donovan et al, 2017. doi: 10.1007/s10926-016-9628-3. [COPYRIGHT 2016]

Figure 3 - Flowchart of early intervention program

Reprinted by permission from Springer Nature. Journal of Occupational Rehabilitation. The Effect of a Workplace-Based Early Intervention Program on Work-Related Musculoskeletal Compensation Outcomes at a Poultry Meat Processing Plant. Donovan et al, 2017. doi: 10.1007/s10926-016-9628-3. [COPYRIGHT 2016]

Written by Michael Donovan from the University of Queensland in collaboration with Workplace Health and Safety Queensland.