Zip ties on scaffolding

Zip ties are commonly used for non-structural applications where they are not exposed to direct loading, such as when attaching shade cloth to the inside of mesh as a control measure against the risk of falling objects.

In Queensland, zip ties are increasingly being used in structural scaffolding applications instead of using an existing proprietary component for that application.

Scaffolding manufacturers rarely make mention of the suitability of zip ties to carry loads or be suitable in these applications. The risks of such applications include a person or objects falling from heights.

In some situations, load-rated zip ties can potentially mislead workers into presuming they are adequate for a number of scaffolding applications. Unlike proprietary components, plastic zip ties have not been performance tested for structural scaffolding applications. While zip ties are load rated, the load rating is only for tensile (pulling) loads and not for shear (cutting) loads. In some of the following examples, zip ties could be subjected to shear or tensile forces that may be well in excess of their maximum allowable load. Experience has demonstrated that the zip ties can be cut through by the edges on scaffolding planks, such as when a worker's foot inadvertently makes contact with a scaffolding plank.

In accordance with the Work Health and Safety Regulation 2011 all prefabricated scaffolding requires design registration before it is used in Queensland. When the design registration application was originally made, drawings of all of the components should have been submitted with the application and the scaffolding design verified by a competent person, such as a professional engineer, to an appropriate design standard (e.g. Australian Standard Plant design verification Scaffolding licences HWSA – Scaffolding checklist AS/NZS 1576 Scaffolding). Using zip ties instead of proprietary scaffolding fittings is unlikely to have been approved by the scaffolding manufacturer and design verifier and is therefore outside of the manufacturer's directions.

While the Scaffolding Code of Practice 2021 (PDF, 1.63 MB) does not provide specific guidance on the use of zip ties, there is relevant guidance in Section 5.7:

- Metal planks lapped on other metal planks should be secured using fixings such as double tie wire or strapping.

- Tie wire or any other system that is not structurally rated should not be used to secure planks on hop-up brackets.

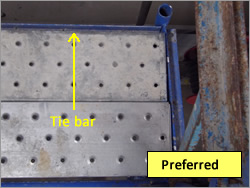

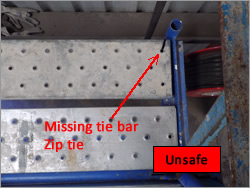

- All hop-up brackets should be provided with tie bars to stop brackets from spreading apart, causing planks to dislodge, unless otherwise specified by the scaffold designer.

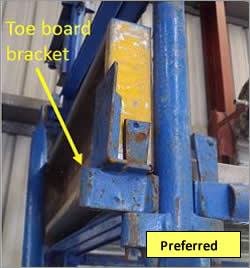

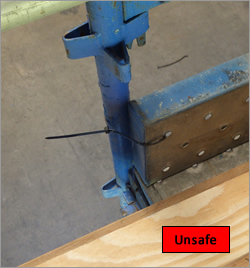

The following photographs compare some examples of scaffolding erected using proprietary products and plastic zip ties. The photographs are examples of unsuitable applications, but there may be others.

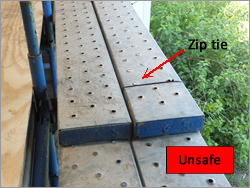

Unsafe examples of zip ties

- Two and three board hop-up brackets

Install tie bars on all two and three board hop-up brackets to prevent the brackets from spreading apart and causing planks to dislodge.

Note: One board hop ups are generally designed without tie bars.

- Toe board brackets

Use toe board brackets to secure toe boards

- Lapped planks on hop up brackets

- Modular stair systems

Use proprietary system bolts to secure handrails to stair cases.

- Edge protection

Top and mid rails

Non load bearing use of zip ties

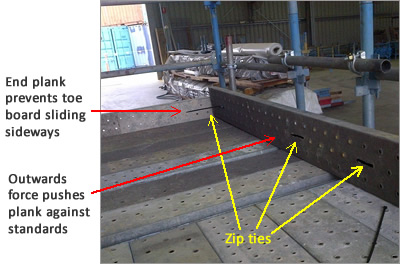

In examples 6 and 7 the typical loading applied to the toe board will be directly applied to the scaffolding standards. Please note that while zip ties could be used in this way, the example is unusual.

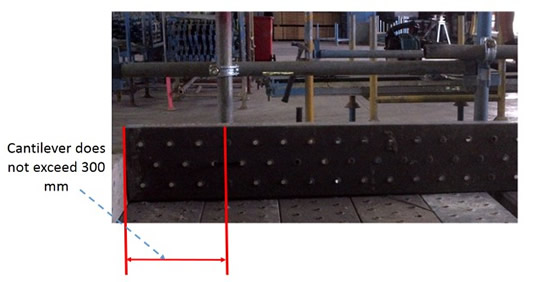

Note: the cantilever (overhang) should not exceed 300 mm.

- Example of zip ties on a toe board where direct loading is not transferred to the zip tie

- Same example as example (6) showing maximum cantilever (overhang) of 300 mm.

- Zip tie used to fasten shade cloth on inside of mesh

Example 8 shows a zip tie connecting shade cloth to the inside of steel mesh – as a falling objects control measure. In this example, the zip tie is being used to fasten the shade cloth to the mesh. Any loads applied by materials ejected from the building will be applied directly to the steel mesh and then to the scaffolding tubes. This shows an acceptable use of a zip tie.

Note: Zip ties in this application can be difficult to install. Alternative connectors can be used. One example is a push-on metal clip.

Zip tie used to fasten shade cloth on inside of mesh

Summary

Unless provided with documented advice to the contrary from the scaffolding designer (i.e. a professional engineer) or manufacturer WHSQ considers the use non-proprietary or non-structurally rated products, such as zip ties as unacceptable for structural loading for the following reasons:

- The manufacturer of the modular scaffolding system has not verified their use for structural applications.

- These components have not been designed for shear loads and their rated tensile strength is relatively low.