Risk management

This page has information about how to identify hazards, assess, manage, monitor and review risks of slips, trips and falls risks at your place of work.

On this page:

Identify hazards

Identifying hazards is the first step to determine exactly where slips, trips and falls (STF) can or have occurred in your workplace. You can find out this information by:

- talking to workers and supervisors, they can provide valuable information about potential hazards

- inspecting the premises for slip or trip hazards. Refer to the Guide to preventing slips, trips and falls at work (PDF, 1.38 MB)

- sketching or mapping a layout of the work area and marking on it where slip and trip incidents or hazards have been reported, and

- reviewing available records such as incident and injury reports as well as workers' compensation claims, previous inspection reports.

Assess the risk

The next step is to assess the slip or trip risks.

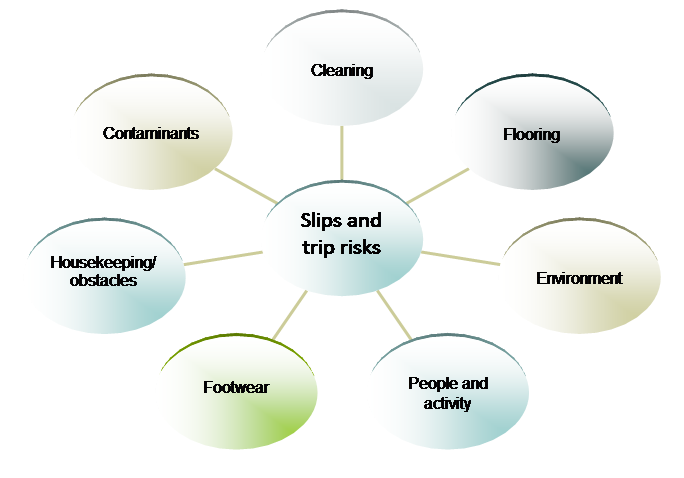

- Usually it is a combination of factors that create the risk. These factors are presented below.

- Use the information gathered above (i.e. from injury reports, checklist etc.) and also consider:

- how many people are exposed

- the consequences of the slip or trip – a slip or trip with or without a fall can be more serious if it occurs near hot, sharp or moving objects, or at a height, such as near stairs

- how often the situation occurs.

- It is important to have a look at all the risk factors so that the solution properly addresses the risks.

Fix the problem

Look at the assessed risks and decide what needs to be done to eliminate or reduce the risks and how quickly these control measures need to be implemented. The Guide to preventing slips, trips and falls at work (PDF, 1.38 MB) provides practical and useful ways to effectively reduce the risk.

Importantly, using the hierarchy of control guides you to choose a solution that most effectively eliminates or minimise the risk. There are different types of control strategies to eliminate or reduce the risks. These are listed below in order of their effectiveness.

It may involve a single control measure or a combination of two or more different controls to best address the risk. Aim to include an elimination or design type of control when considering solutions.

Examples of control measures | |

|---|---|

Elimination |

|

Redesign of the environment, activity, work process or equipment |

|

| |

Engineering e.g.:

| |

Administrative |

|

Personal protective equipment |

|

To implement the most effective controls you should:

- start at the top of the hierarchy of control

- allow workers to trial controls and get their feedback before decisions are made to make them permanent

- develop work procedures to ensure that controls are understood and responsibilities are clear

- communicate the reasons for the change to workers and others

- ensure that any equipment used is properly maintained

- provide training to ensure workers can competently implement the risk controls.

Monitor and review

Control measures that have been put in place must be monitored and reviewed, and, if necessary, revised to make sure they work as planned. Check that no new measures are introduced.

You should review control measures:

- when the control measure is no longer effective

- before a change that is likely to create a new or different risk

- if a new hazard is identified

- if consultation indicates a review is necessary

- if a health and safety representative requests a review.

Refer to the web guidance for advice on managing the issues that contribute to risk including: contamination, cleaning, floor surfaces, housekeeping, obstacles, environment, people and activity, external areas, footwear and design considerations.